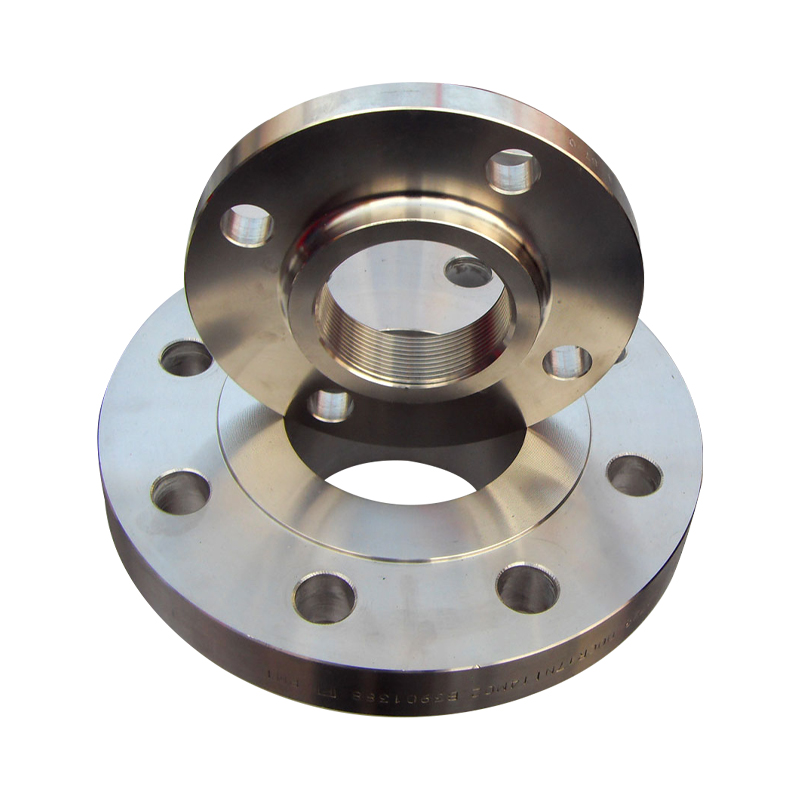

OEM CE Certification Inconel 600 Flanges Manufacturers - Socket Weld Flanges – Topwill

OEM CE Certification Inconel 600 Flanges Manufacturers - Socket Weld Flanges – Topwill Detail:

Socket Weld Flanges

product description:

Size

Socket weld flange:1/4″-4″

DN8-DN100

Pressure

America Series:Class 150 ,Class 300, Class 600, Class 900A ,Class 1500,Class 2500.

Europe Series:PN2.5,PN6,PN10,PN16,PN25,PN40,PN63,PN100,PN160,PN250,PN320,PN400.

Flange Facing Types

America Series:Flat face(FF),Raised face(RF),Tongue(T),Groove(G),Female(F),Male(M),Ring type joints face(RJ/RTJ)

Europe Series:Type A(Flat Face),Type B(Raised Face),Type C(Tongue),Type D(Groove),Type E(Spigot),Type F(Recess),Type G(O-Ring Spigot),Type H(O-Ring Groove)

Material

Carbon steel: ASTM A105,ASTM A105N,GB 20,C22.8.

Alloy steel: ASTM/ASME A182 F1-F12-F11-F22- F5-F9- F91

Stainless steel: ASTM/ASME A182 F304-304L-304H-304LN-304N

ASTM/ASME A182 F316-316L-316H-316LN-316N-316Ti

ASTM/ASME A182 F321-321H, F347-347H

Low temperature steel: ASTM/ASME A350 LF2.

High performance steel: ASTM/ASME A694 F42 , F52, F56, F60, F65, F70

Standards

ASME ANSI B16.5,ASME ANSI B16.47.

API 605,API 6L.

MSS SP 44

CSA Z245.12

EN1092-1,EN1759-1.

DIN2630,DIN2631,DIN2632,DIN2633,DIN2634,DIN2635,DIN2636,DIN2637,DIN2638.

BS1560,BS 4504,BS 10.

AFNOR NF E29-200-1

ISO7005-1

AS2129

JIS B2220

UNI 2276. UNI 2277.UNI 2278 .UNI 6089 .UNI 6090

Industrial Processes

Die forging,Machining.

Application forSocket weld flange

Natural gas,chemical,petroleum,ship building,marine,paper making, metallurgy, electric, power, boiler , etc.

Product detail pictures:

Related Product Guide:

We stick to our enterprise spirit of "Quality, Efficiency, Innovation and Integrity". We aim to create more value for our customers with our rich resources, advanced machinery, experienced workers and excellent services for OEM CE Certification Inconel 600 Flanges Manufacturers - Socket Weld Flanges – Topwill , The product will supply to all over the world, such as: Nepal, Belize, Pakistan, After years' creating and developing, with the advantages of trained qualified talents and rich marketing experience, outstanding achievements were gradually made. We get good reputation from the customers due to our good solutions quality and fine after-sale service. We sincerely wish to create a more prosperous and flourishing future together with all the friends home and abroad!

The company has a good reputation in this industry, and finally it tured out that choose them is a good choice.